you are currently visiting our website in a browser that is not supporting our website.

Welding, cutting, inerting

Discover Linde's extensive range of welding and cutting gases. Choose the packaging that suits your operations for a high-quality, comfortable and safe solution.

-

Filter

- 52 Products

-

-

- Select More than 1 Item

- Compare

Acetylene

For gas welding and cutting. For other applications see 'Product details'.

Acetylene offshore

For gas welding and cutting. For other applications see 'Product details'.

Acetylene NEMO PLUS

For gas welding and cutting. For other applications see 'Product details'.

Argon 4.6

Various applications in welding and cutting techniques, metal treatment and inerting.

Argon 4.6 NEMO PLUS

Various applications in welding and cutting techniques, metal treatment and inerting.

Argon 4.6 offshore

Various applications in welding and cutting techniques, metal treatment and inerting.

Argon/Nitrogen 98,5/1,5

Argon/nitrogen mixture is an inert gas that offers several advantages when used as a welding gas.

Argon/Hydrogen 65/35

This gas mixture is suitable for plasma cutting of thick stainless steels.

Argon/Hydrogen 95/5

For TIG welding of austenitic stainless steels.

Argon/Hydrogen 98/2

For plasma welding and TIG welding of stainless steel, nickel and nickel alloys.

Backing gas 90/10

Protection of the backside of the weld with corrosion resistant steel, such as stainless steel.

Backing gas 95/5

Protection of the backside of the weld with corrosion resistant steel, such as stainless steel.

-

Filter

Filter - 99 Products

-

-

[ Heat treatment Heat treatment You benefit from decades of experience and the knowledge gained from countless successfully completed projects Heat treatment involves controlling numerous parameters to achieve specific metallurgical properties in a given material. We offer technologies and in-depth know-how to enable precise control of key parameters in the various heat treatment processes. In addition, we offer the full range of gases to form furnace atmospheres. Please select a heat treatment application Annealing → Hardening → Cryogenic treatment → Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ About Linde Gas Benelux About Linde Gas Benelux Building on grass roots Linde Gas Benelux is the global market leader in the production and sale of technical, medical and specialty gases and gas mixtures, and on the marketing and distribution of gas related equipment, systems and services, as well as the engineering of turnkey plants. Industrial gases are being used all over the world, all the time, day and night. Regardless area - welding, cooling, heating, industrial cleaning or the lab analyses - gas is present. Industrial gases from Linde play a crucial part in metallurgical processes, in chemical industry, food industry, environmental protection, while manufacturing glass and electronics, construction, pharmaceutical industry and research and development. Company profile Procurement Suppliers evaluation Code of ethics Company profile With its innovative concepts, Linde plc. is the world’s market leader in industrial and medical gases and gas mixtures. Furthermore, Linde Engineering constructs turnkey industrial plants. Being a technology leader as well, it is our task to constantly raise the bar. Traditionally driven by entrepreneurship, we are working steadily on new high-quality products and innovative processes. A glance at Linde plc. Linde gases are applicated in virtually all sectors of society: In the chemical, metal and food industry, in education and in science, but also in hospitals and patients at home. But Linde offers more. We create added value, clearly discernible competitive advantages, and greater profitability for our clients and prospects. Each concept is tailored specifically to meet our customers’ requirements – offering standardized as well as customized solutions. This applies to all industries and all companies regardless of their size. If you want to keep pace with tomorrow’s competition, you need a partner by your side for whom top quality, process optimization, and enhanced productivity are part of daily business. However, we define partnership not merely as being there for you but being with you. After all, joint activities form the core of commercial success. Responsibility Linde acts responsibly towards its shareholders, business partners and employees and is committed to society and the environment – in every one of its business areas, regions and locations across the globe. We are committed to technologies and products that unite customer value and sustainable development. Procurement Managing our supplier relationships to ensure fair, competitive prices for our customers At Linde, we are committed to offering our customers the best products at competitive prices through an equitable tendering process. Global Procurement issues requests for proposals for products/services that we require. This global organisation also draws up and maintains standard agreements with key suppliers. Global management of supplier relations brings synergy and efficiency gains to both our customers and suppliers. You can find our General Terms and Conditions of Purchase here. . Suppliers evaluation As part of our Suppliers Management, key suppliers are evaluated by Linde. The purpose of the evaluation is to measure the performance of our key suppliers in order to maintain our competitiveness and meet excellence in terms of cost, quality and service. Suppliers that do not meet the Linde requirements will be blocked or deleted from our vendors panel. The following criteria are taken into consideration for the assessment: Health Safety Environment (HSE) Quality, Delivery/Logistics Levering/Logistiek Innovation Commercial Operational Should you have any question, please contact your local Tactical Buyer. ]

-

[ Digital delivery documents Digital delivery documents Access to your delivery documents anytime and anywhere At Linde, we would like to contribute to making your daily work easy and smooth and reduce paper consumption. That's why, since 31 March 2022, we have gradually replaced the paper delivery notes (which our driver leaves for you) with a digital copy. In practice, this means for you: no more archiving, no more folders, no more time-consuming searching for documents. This saves you valuable time and brings you one step closer to a paperless office. You can view your digital delivery documents at any time in the 'my account' area of the customer portal. You'll have your records at hand at all times, as access to the Linde Gas customer portal is of course possible not only via PC, but also via cell phones and tablets. How does it work? Once our drivers have completed the delivery of your order, you can sign for delivery on a mobile device that our drivers have with them. The digital delivery document can then be viewed in the Linde Gas customer portal within two working days. Rather receive your delivery document via email? In addition to viewing delivery documents in our webshop, we also offer you the option of receiving these documents automatically by email. If your email address is registered, you will receive the signed delivery document by email within 1 hour after delivery. Choose below the product you purchase from us to register or change the email address for that product. Cylinder gases For this, you can change the email address yourself in the 'my profile' area of our customer portal. Register or change email address Nitrogen / Carbon dioxide vessels For this, you can change the email address yourself in the 'my profile' area of our customer portal. Register or change email address Bulk (tanks) The change for this goes through our bulk department. Click on the link below to enter your information. Register or change email address × Digital delivery documents I hereby authorize Linde Gas Benelux to send delivery documents to the email addresses listed below. Only one e-mail address per tank can be registered. ]

-

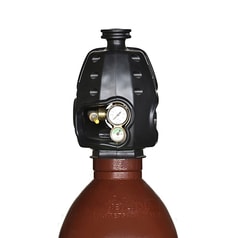

[ Digigas DIGIGAS® De digitale oplossing voor uw gasbeheer Controleer eenvoudig online het niveau van uw cilindergas en laat gassen automatisch bijleveren: DIGIGAS® is de slimme oplossing voor uw gasbeheer. Vrijblijvend contact opnemen Waarom kiezen voor DIGIGAS®? Via een online dashboard monitort u de inhoud van al uw gascilinders U ontvangt een waarschuwing via e-mail en/of SMS als de gasinhoud een minimum niveau bereikt U zit nooit meer zonder gas en daarmee voorkomt u een productiestop U hoeft de gasinhoud van cilinders niet handmatig meer te controleren U heeft zelfs de optie om de benodigde gassen automatisch opnieuw bij Linde te bestellen DIGIGAS® service pakketten DIGIGAS® is momenteel verkrijgbaar in twee verschillende service pakketten: DIGIGAS® Notify Altijd en vanaf elke locatie inzicht in uw gasvoorraad, met eigen instelbare berichten die uw waarschuwen wanneer de minimum gasinhoud is bereikt. DIGIGAS® Order Deze service gaat een stap verder en plaatst automatisch een herhaalorder als de gascilinders de drempelwaarde heeft bereikt. Dat scheelt tijd doordat een handmatige stap in het proces nu geautomatiseerd is. Hoe werkt het DIGIGAS® systeem? U monteert de slimme sensor op een bestaande drukregelaar of cilindercentrale die een reservepoort hebben aan de hogedrukzijde. De slimme sensor zendt vervolgens draadloos de druk-en temperatuurgegevens naar een ontvanger (repeater). De repeater stuurt deze data vervolgens via een mobiele verbinding naar de cloud. Hier worden de gegevens geanalyseerd, waarbij de gasinhoud wordt omgezet in een percentage. De gasinhoud van uw cilinders kunt u 24/7 inzien op een online dashboard vanaf uw computer, gsm of tablet. DIGIGAS® installeren Stap 1 Steek de stekker van de repeater (ontvanger) in een stopcontact en bevestig deze aan de muur. Stap 2 Schroef de slimme sensor in de poort van het reduceertoestel of de cilindercentrale. Stap 3 U scant de QR-code op de slimme sensor en voert de cilindergegevens in via het installatieprogramma. Stap 4 Is het installatieproces voltooid? U kunt nu uw cilindervoorraad inzien en notificaties instellen. DIGIGAS® downloads DIGIGAS® brochure DIGIGAS® datasheet DIGIGAS® handleiding Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ Freezing & cooling Freezing and cooling Refrigeration and freezing of foodstuffs The benefits of decades of experience in cryogenic refrigeration and freezing One of the main challenges in the food industry is the effective control - or better yet, elimination - of bacterial activity. One of the most important weapons in the fight against bacteria is refrigeration and freezing. When the temperature drops below freezing, the growth of microorganisms decreases rapidly. This is caused not only by lowering the temperature of the product, but also by decreasing water activity: there is no longer free, liquid water, so microorganisms no longer have water to metabolize. More information Cryogene koel- en vriestoepassingen met ijskoude voordelen Chilling food reduces the risk of bacterial growth. Rapidly cooling food products (also known as flash freezing or cryogenic freezing) further reduces this risk. Cryogenic freezing also preserves the natural quality of food. When a product is frozen, ice crystals form. The smaller these crystals are and the more evenly distributed they are in a product, the better the quality and flavor are preserved. The only way to ensure that small ice crystals form and are evenly distributed throughout the food product, both inside and outside the cells, is to freeze the product at cryogenic temperatures. Years of experience As the global leader in modern food refrigeration and freezing methods, we have been delivering innovative solutions for decades and have the expertise like no other to help you with the most complex challenges. We offer a full range of cryogenic freezers for fast inline freezing and cooling. Our cryogenic solutions use carbon dioxide and nitrogen gases to rapidly lower the temperature of food products for both improved processing and longer shelf life. Cryogenic liquid gases can also be used to effectively, flexibly and silently maintain frozen and chilled food items at precise temperatures during transport. Carbon dioxide snow (solid CO2), also known as 'dry ice', is a highly effective refrigerant that is easy to use. At atmospheric pressure, liquid carbon dioxide changes to a solid form at approximately -¬79ºC. CO2 in solid form is a very effective means of cooling products in mixers, bins, cans, glasses, boxes and combos. CO2 snow is most effective when used in conjunction with custom snow horns and nozzles. We have a range of specific expansion nozzles that ensure efficient snow production and rapid cooling. We also offer a variety of snow horns, from hand-held and portable units to permanent installations. All of our cryogenic equipment is designed for the highest efficiency and meets the highest hygiene standards. Here you can find the selection of our Linde Gas CRYOLINE® freezers CRYOLINE® MT - Tunnel freezer This all-purpose freezing tunnel combines user-friendly operation with the best possible hygienic design. Adjustable fans and variable gas injection ensure optimal heat transfer. The patented exhaust air solution convinces with efficiency and user-friendliness. The attractive exterior design hides all motors and piping and is easy to clean. There are several options in terms of belt size. Product examples: Meat and meat products Dairy products Fish and seafood Baked products Cooked meals and other ready-to-eat products CRYOLINE® CW - CRYOWAVE freezer The patented multifunction freezer combines the high-quality IQF freezing properties of the CRYOWAVE system with the high efficiency of the tunnel freezer. It can be switched from IQF mode to standard tunnel mode in an instant. The technology of a Standard Tunnel combined with an adjustable mechanical suspension system. This allows the product to be agitated from the belt during the processing time. This mechanical agitation is also called the Cryowave. The strength can be adjusted depending on the size and weight of the product. Product examples: Pizza toppings Meatballs Shrimps and prawns Mushrooms Currants Pasta IQF products Sliced and diced products CRYOLINE® CWI - IQF freezer The next generation of IQF freezers that is a combination between CRYOWAVE & impingement technology, all to get higher heat transfer and freeze more efficiently. Product examples: Meat Ready meals Seafood Fruit Groots IQF products CRYOLINE® SC - Super contact freezing tunnel For sensitive products, the CRYOLINE® SC uses a patented disposable film transport system. It easily freezes and cools liquid or marinated products, for example. It is also suitable for pre-freezing soft products such as fish or chicken fillets. Thanks to the one-way conveyor belt, a wide variety of products can be processed during production. Interim cleaning of the belt is not necessary. Another advantage over a mesh belt is the prevention of belt marks on the product. Product examples: Fish fillets Marinated products Chicken breast fillets, fillet steaks Purees, pancakes Pasta Liquid and semi-liquid products CRYOLINE® PE - Pellet freezer The patented CRYOLINE® PE forms liquid or semi-liquid foods - including solids such as onions - into pellets in the recesses of its solid stainless steel conveyor before they are fully frozen. The system is particularly suitable for producing sauce pellets for ready meals. The consumer thaws only as many pellets as he needs for a particular dish. The compact freezer, delivered in one piece, is ready for immediate use and requires minimal assembly and start-up times. The standard pellet size is 30 x 30 x 6 mm, but the shape and size can be customized. Product examples: Sauces Purees Soups Pasta CRYOLINE® PEC - Tunnel freezer The bigger and more complete brother of the PE. Cryoline PE 800 is a freezer that can freeze uniform pellets from liquid form. Unlike the PE, the PE 800 consists of a double pellet belt with a contiguous MT freezer to get a whole frozen product. Product examples: Prepared foods Sauces Food service CRYOLINE® TI - Tunnel freezer TI is a tunnel freezer that uses top-down Impingement technology to increase heat transfer. This contributes to the efficient and optimizes cryogenic consumption. Product examples: Meat protein Seafood Baked goods Prepared meals Dairy products Fruits and vegetables Pasta CRYOLINE® SI - Immersion bath IQF freezer The CRYOLINE® SI is an all-in-one solution with an immersion bath for liquid nitrogen and a downstream freezing tunnel for the highest quality loose-rolled food products (IQF = Individually Quick Frozen). The CRYOLINE®SI is suitable for a wide range of IQF products, such as shrimp, sliced/ diced fruit, vegetables or meat and individual components for the production of ready-to-eat foods. The freezer is designed for production capacities up to approximately 900 kg/h. The CRYOLINE®SI comes complete with a specially adapted feed vibratory conveyor. This ensures a continuous product flow and prevents the products from sticking to the infeed. CRYOLINE® CS - Compact spiral freezer The CRYOLINE® CS, with its patented self-stacking spiral conveyor and small footprint of only 2.5 x 3.4 m, has a high freezing or cooling capacity. Its unique design makes efficient use of refrigerant. The self-stacking conveyor minimizes the risk of clogging and jamming of the conveyor. Unlike most spiral freezers, this unit is delivered in one piece - for fast installation and immediate commissioning. Product examples: Meat and meat products Dairy products Fish and seafood Baked products Cooked meals and other ready-to-eat products CRYOLINE® CX - Spiral freezer A medium size Spiral freezer with a 600 mm patented self stacking belt. The Cryoline Cx has a smaller size, higher production capacity and higher efficiency than current cryogenic spiral freezers. The dense plate belt ensures minimal imprint on the product. Specially designed for full crust freezing or chilling of products. The CX can operate 10-20% more efficiently, depending on the product, than standard cryogenic spiral freezers. The model has been designed taking into account the latest safety risks and has a hygienic design. It has multiple doors for easy cleaning. Product examples: Meat Poultry Seafood Baked goods Prepared meals CRYOLINE® XF - Spiral freezer The CRYOLINE® XF is a high-performance spiral freezer designed for high production capacities. Thanks to the patented cross-flow technology, high flow rates can be achieved and freezing times shortened. The smaller overall dimensions reduce not only cold loss but also space requirements. The freezer is designed with hygiene in mind and is easy to clean. Product examples: Meat and meat products Dairy products Fish and seafood Baked products Cooked meals and other ready-to-eat products CRYOLINE® CF - Freezer The CRYOLINE® CF is a freezer for freezing or cooling all foods in batch. It offers modern, process-oriented control for precise control of various recipe menus. The design, entirely in stainless steel, guarantees the best possible hygiene and easy cleaning. In addition, the control system allows complete traceability of production data by batch. Product examples: Meat and meat products Dairy products Fish and seafood Baked products Cooked meals and other ready-to-eat products ACCU-CHILL® LX The ACCU-CHILL® LX is a bottom injection system for cryogenic media in mixers, kneaders and stoves of various designs. It injects a certain amount of coolant directly into the product mass. The system can be mounted on existing or new machines. The unique valve closes flush with the inside of the container, preventing the accumulation of products. This guarantees the highest level of hygiene. Product examples: Meats for shaping Liquid products Sweets Sauces Other meat products before shaping Controlled tumbling By direct cooling with cryogenic gases, the temperature during tumbling can be controlled quickly and safely. This creates standardized, automatable and reproducible process conditions. Benefits: Optimal molded meat quality Inhibition of germ growth due to low temperatures No chemical or sensory changes in the meat Avoidance of weight loss Inhibition of oxidation processes Slicing With modern high-performance slicing machines, in addition to high processing speed, a homogeneous product appearance is achieved. With much softer products, such as pork tenderloin or fish, the slicing result and especially the amount of waste can be optimized by freezing the products using cryogenic technology. Advantages: Uniform cutting pattern down to the last slice Less wear, waste and downtime Increase in cutting speed by up to 20% Short freezing times Possibility of cutting even thinner product slices Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ SECCURA bulk management SECCURA® bulk management Automating tank deliveries with our SECCURA® gas supply service Managing bulk inventories of gases such as nitrogen, oxygen, carbon dioxide and argon and ordering new stock takes time. Our SECCURA® service relieves you of these routine tasks, increasing safety and leaving you free to concentrate on your core business. More information SECCURA® bulk management flyer We use remote monitoring functionality, electronic sensors and a tank computer to constantly measure and log pressure and fill levels. This data is electronically transferred to our Service Centre. The dispatchers at Linde Gas immediately order new supplies if the tank level drops below the defined threshold. Key features Tank fill level and pressure electronically monitored and transferred to the Linde Gas Benelux Service Centre Replenishment orders sent automatically to our Distribution Centre Tank filled by Linde driver 24-hour hotline offering technical support Advantages Guaranteed uninterrupted availability of gas supply Maximum safety during refill procedure Time and cost savings through outsourcing of stock monitoring, ordering and handling Cost savings through delivery and stock optimisation and avoidance of express surcharges Increased safety through early detection of leakages Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ Data sheets Data sheets Click below on the type of data sheet you are looking for. Product and safety data sheets can also be found at the bottom of individual product pages. Data sheets, brochures and user manuals can also be searched by product. Safety data sheets Product data sheets Certificates & (ISO) standards ]

-

[ Linde Green Linde Green: Pioneering Sustainable Air Gases Taking your green agenda to the next level: air gas offer produced with 100% renewable energy sources. What is Linde Green? Why Linde Green? Green production Full certification Video Linde green products CO2 reduction equivalents Ready to go green? Achieving green goals together Our planet is changing at an alarming rate, and we're already feeling the impacts. As climate change and other environmental issues take center stage and affect all areas of our lives, companies are dealing with increased pressure from regulators, investors, and communities to reduce their carbon footprint. At Linde, we continuously live our mission of making our world more productive. Through our high-quality solutions, technologies, and services, we provide a competitive advantage to our clients, helping them improve their productivity, energy efficiency, and environmental performance. Sustainability, as one of our principal values, inspired our latest product line: Linde Green. In a Nutshell All you need to know about Linde Green ✓ Old Product - New Production Approach Linde Green products offer the same benefits as conventional Oxygen and Nitrogen. The only thing that differs is the production approach. ✓ 100% Renewable Energy Sources In the production of Linde Green, we use solely renewable energy, such as solar, wind power, geothermal, biomass, and hydroelectric plants. ✓ 99% Less Carbon Emission* Linde Green Oxygen and Nitrogen have significantly lower level of CO2 emission, compared to the conventionally produced gases - 99% lower.* ✓ Proof of CO2 Reduction Each Linde Green customer will receive a monthly certificate about the accounting-wise CO2 reduction, based on the monthly consumption of Green Oxygen or Nitrogen.* ✓ Certified Production Process Every step of our production and commercial process has been certified by TÜV SÜD and complies to their standard “Accounting EE”. Reducing CO2 Footprint: 99% Cleaner Oxygen and Nitrogen* The Linde Green product offer includes air gases – Nitrogen and Oxygen, produced with 100% renewable energy sources. This production approach results in a significantly lower CO2 footprint compared to the conventional production process. And when we say significant, we mean up to 99% less carbon emission.* Embracing this path, Linde is one of the first companies to introduce air gases with a lower CO2 footprint and enables, to reduce the CO2 footprint through the consumption of our customers. How? Upon each purchase of Linde Green gases, we will provide you with a Green Certificate, stating the exact carbon footprint reduction achieved using our green products.* Rethinking our production process To help our customers improve their environmental performance by reducing the carbon footprint of Oxygen and Nitrogen, Linde is continually inventing new applications and more efficient ways of air separation. The same happened with Linde Green, where we embraced a brand-new production approach. To produce Linde Green products, we use exclusively renewable energy sources such as solar, wind power, geothermal, biomass, and small hydroelectric plants, all of which are less harmful to the environment than fossil fuels. And the result? Linde Green Oxygen and Nitrogen bring a significant reduction of CO2 emission compared to the use of conventional electricity.* TUV Süd: Partnering Our Green Approach Every step of our production and the commercial process has been examined and accredited by TÜV SÜD, the well-known global auditing and certification service provider. As a universally recognized symbol of safety, security and sustainability, TÜV SÜD is partnering our green approach, ensuring that our product offer complies with their standard “Accounting EE”. TÜV SÜD is our trusted partner of choice. Together, we have a proven track record of large-scale projects and innovation fields, such as hydrogen technology. For the Linde Green product line, they offer both certifications of energy trading from renewable sources and accounting greenhouse gas emissions for the supply of electricity. How much CO2 will be reduced by using renewable energy?* CO2 reduction from 100 tons of Linde Green Oxygen… … equals the carbon sequestered by 827 tree seedlings grown for 10 years.** CO2 reduction from 100 tons of Linde Green Oxygen… … equals the greenhouse gas emissions from 10 passenger vehicles driven for one year.** * Our Linde Green products (excluding transport) are manufactured using energy from 100% renewable sources, which has reduced the stated amounts of CO2 equivalents according to the CO2 balance. The stated amounts are based on a comparison with similar products manufactured using conventional electrical energy. Transport is conventional and is not taken into account. ** The CO2 reduction comparison data on this website was calculated on the official site of the United States Environmental Protection Agency (EPA): https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator Our products The following table gives an overview of our extensive product range, including green variants, which are in line with our commitment to environmental sustainability. Current product Green product 2230901 Nitrogen liquid Foodgrade E941 2230701 Nitrogen liquid Foodgrade E941 - Green 2420901 Nitrogen liquid 2420701 Nitrogen liquid - Green 2420911 Nitrogen Liters 2420711 Nitrogen Liters - Green 2010901 Oxygen liquid 2010701 Oxygen liquid – Green 3190701 Hydrogen trailer Fuel Cell grade – Green 2140901 Oxygen liquid Foodgrade E948 2140701 Oxygen liquid Foodgrade E948 - Green 2070901 VERISEQ Liquid Nitrogen 2070701 VERISEQ Liquid Nitrogen - Green 2150901 VERISEQ Liquid Oxygen 2150701 VERISEQ Liquid Oxygen - Green 3200901 Liquid Hydrogen 5.0 3200701 Liquid Hydrogen 5.0 - Green 2160901 Oxygen liquid Kiwa-ATA 2160701 Oxygen liquid Kiwa-ATA – Green 2050901 Oxygen 3.5 liquid 2050701 Oxygen 3.5 liquid - Green 2411820 MEDISPEED® 6 liter (met inkepingen) 2411720 MEDISPEED® 6 liter (met inkepingen) 2411811 MEDISPEED® 1,5L Nitrogen 2411711 MEDISPEED® 1,5L Nitrogen 2411818 MEDISPEED® 8L 2411718 MEDISPEED® 8L 2020901 CONOXIA® Liquid (bulk) 2020701 CONOXIA® Liquid (bulk) 2200902 MEDISPEED® Liquid Med N2 2200702 MEDISPEED® Liquid Med N2 2410911 MEDISPEED® Lin service 2410711 MEDISPEED® Lin service 2411819 MEDISPEED® 6 liter (dichte nek) 2411719 MEDISPEED® 6 liter (dichte nek) Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ About Linde Learn more about our commitment to our mission of making our world more productive Our Company Every day around the world, our people are inspired by our mission of making our world more productive. As a leading global industrial gases and engineering company, we deliver high-quality solutions, technologies and services which are making our customers more successful and helping to sustain, decarbonize and protect our planet. Learn more about Linde → Making Energy Clean We are actively contributing to the widespread adoption of clean energy, such as hydrogen and its derivatives, and significantly cutting emissions through carbon capture, utilization and storage technologies. We are committed tomaking our world more productive, sustainably through our operations and engineering expertise, established infrastructure and strong investment in decarbonization projects and R&D. Learn more about our role in the clean energy transition → Community Engagement Community is a corporate value at Linde. Connecting with the communities where we live and work and fostering resilience are key priorities for us. Our global giving and community engagement efforts frame a wide variety of impactful projects in each of our businesses across key focus areas. Through efforts that include charitable contributions, volunteering, and strategic investments, our people live our mission of making our world more productive every day Learn more about Linde’s Community Engagement Program → Diversity, Equity & Inclusion at Linde With operations in more than 80 countries -- diversity isn't something that Linde does, it's simply who we are: Linde serves a diverse range of customers. Our engineering, gases and application technologies are essential to businesses of every type and size, as well as individuals all over the world. Our people are diverse. Our employees around the globe each bring their diverse backgrounds, skills and experiences and help foster a collaborative, innovative and performance-driven workplace that helps achieve our mission of making our world more productive. At Linde, inclusion is a core value. That means we strive to provide an environment where individuals of all backgrounds and experiences feel comfortable bringing their ideas to the table and are given the opportunity to be heard and to contribute. Learn more about diversity, equity & inclusion at Linde → Guided by Integrity Integrity is one of our core values. It is at the heart of everything we do and say at Linde. Ethical, respectful, fair, and compliant behaviors build transparency and trust, creating a solid basis for growth and prosperity to the benefit of our employees, customers, suppliers, markets and communities. Learn more about our commitment to integrity → Building a Robust Supply Chain We value the role our suppliers and contractors play in our ability to deliver on the promises to our customers and to the communities is which we operate. We choose our suppliers carefully based on merit as well as alignment with our values, with Linde’s Supplier Code of Conduct and Code of Business Integrity. We continue to foster diversity and local sourcing. Further, we actively invest in our supplier relationships. Learn more about Linde's supplier guidelines and standards → Zero Today Zero Today means we are driving toward zero incidents and zero injuries today and every day. The Values, Commitments and Safety Principles in our Health, Safety and Environment (HSE) Policy are the foundation for Zero Today at Linde, and our core value of Safety keeps us focused every day on what matters most: the well-being of our people, the environment and the communities in which we operate. Learn more about our commitment to safety, health, environment, and quality → Sustainability in Focus At Linde, we are actively engaged in efforts to reduce our own footprint as part of our commitment to protect our planet for the long term. At the same time, we are helping our customers to improve their environmental performance. We deliver on our commitment to sustainability through a broad range of concrete measures focused around four key priority factors, which are: Climate Change Safety, Health and Environment People and Community Integrity and Compliance Learn more about how we are helping to sustain and protect our planet → Why Linde Linde is a leading global industrial gases and engineering company with 2024 sales of $33 billion. We live our mission of making our world more productive every day by providing high-quality solutions, technologies and services which are making our customers more successful and helping to sustain, decarbonize and protect our planet. Our industrial gases and technologies are used in countless applications including production of clean hydrogen critical for the energy transition, life-saving medical oxygen and high-purity & specialty gases for electronics, among others. For over 50 years, Linde has been a global leader in hydrogen and is leveraging its engineering capabilities, along with a significant asset base and expertise, to make cleaner energy a reality worldwide. Linde has an exceptional team with a business owner mentality delivering best-in-class financial performance with unwavering capital discipline. Learn more about Why Linde → ]

-

[ Aluminum Aluminum Demonstrated increases in productivity and efficiency throughout the aluminum industry value chain Melting is one of the core steps in processing secondary aluminum. This step is highly energy intensive and has a significant impact on both the productivity and total cost of your aluminum production. With Linde's applications, you increase productivity, yield and quality while reducing energy consumption and emissions. More information Brochure aluminium Low-temperature Oxyfuel OXYGON® 400 datasheet OXYGON® brochure LTOF - Low-Temperature Oxyfuel Combustion Technology This industry-leading technology works as follows: Low-temperature Oxyfuel combustion technology dilutes the burner flame by recirculating combustion gases into the flame, lowering the flame temperature. Key features More homogeneous heating of the furnace Higher productivity Energy savings and reduction of CO2 emissions Higher yield due to less dross Extremely low NOx emissions WASTOX combustion process The WASTOX® combustion process allows combustible materials loaded with the base material to be burned directly in the melting furnace. Depending on the requirement, additional oxygen is added to the furnace via lances. Key characteristics Allows a higher content of combustible materials in the feedstock Control of the melting process and emissions Lower energy consumption by utilizing the energy content of the combustible materials Suitable for any furnace ALUMELT WASTOX® WASTOX® represents a combination of oxygen burners with WASTOX® oxygen lances, which break down toxic pollutants directly in the furnace. The WASTOX® control panel simultaneously controls the oxygen lances and the oxygen burner to burn unburned hydrocarbons and/or carbon monoxide (CO) directly in the furnace. Linde's laser system provides process-coupled measurement of flue gas composition. Organic contaminants in the scrap replace fossil fuels. By determining the composition of the flue gas, WASTOX® supports the accurate process-dependent control of the combustion process. With more than a decade of experience in the development and application of WASTOX® technology, Linde is the undisputed innovation leader in this field. This patented and versatile system is successfully used by many customers worldwide, both in rotary kilns with continuous gas flow ("single pass") and in rotary kilns with gas flow through the charging door ("double pass", as in the URTF). Studies by Linde and aluminum partner companies to determine maximum combustion efficiency have shown that fuels react more effectively in a pure oxygen stream than in an oxygen-enriched flame. In trials of recycling used beverage cans with a pure air/fuel burner, 20-50% of the adhering carbon compounds (paint, coatings) were emitted as volatile organic compounds and as carbon monoxide CO. Over-stoichiometric operation with oxygen burners reduced these emissions to 1%. With the WASTOX® oxygen lance and stoichiometric operation of an oxygen burner, even an almost complete combustion with an emission value of less than 0.01% was achieved. AIROX® Combustion Technology Our AIROX® combustion technology allows furnace operators to easily switch between oxyfuel burner operation during the melting process and burner operation with air or oxygen-enriched air during the holding phase. Key features Flexibility through easy change of burner operation from melting to holding phase Higher melting capacity compared to ordinary air burners Lower energy consumption Less CO2 emissions Flushing of melt with technical gases Flushing melt with nitrogen, argon or chlorine/nitrogen mixtures creates a bathing motion in the furnace. This homogenizes the melt, reduces the dissolved hydrogen content and, by reacting with chlorine, removes unwanted alkali or alkaline earth metals and other solid impurities from the melt. Key features Temperature homogenization of the melt Improved heat transfer in the melt Quality improvement of the melt for the subsequent casting process G Oxygen 2.5 PLEASE NOTE: You must log in to order this product Add to cart Argon 4.6 PLEASE NOTE: You must log in to order this product Add to cart Nitrogen 3.0 PLEASE NOTE: You must log in to order this product Add to cart Oxygen 5.0 Instrument PLEASE NOTE: You must log in to order this product Add to cart Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ HFOs & HFO mixtures ]

-

[ Hardening Hardening HYDROFLEX® The Hydroflex control and monitoring system regulates the furnace atmosphere and controls the quantities of externally supplied furnace gases as required. The control system allows an exact adjustment of the furnace atmosphere to the product qualities to be treated and thus a very good reproducibility. Advantages HYDROFLEX® Regulated furnace atmosphere High efficiency High reproducibility Production documentation Easy handling Safe working conditions Environmentally friendly G Nitrogen 3.0 PLEASE NOTE: You must log in to order this product Add to cart Nitrogen 3.0 offshore PLEASE NOTE: You must log in to order this product Add to cart Acetylene offshore PLEASE NOTE: You must log in to order this product Add to cart Acetylene PLEASE NOTE: You must log in to order this product Add to cart Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ Treatment of glass and molds Treatment of glass and molds Fire polishing of glass products for art, tableware, specialty glass or perfume bottles. Top gas burner technology from Linde For optimum results in glass processing, Linde offers a wide range of burners. We are proud to count some of the world's most famous glass manufacturers among our customers. Polishing and fusing Polishing and fusing improve the surface quality of glass. The flames of our special burners strike the glass directly, where they remelt a thin surface layer. Polishing allows any etching processes to be eliminated or minimized, reducing environmental impact and paving the way for a cleaner and safer work environment. Burner technologies Linde's burner systems are based on gas technologies that work either with premixing or naming: HYDROXPOX®: premix technology with oxygen and hydrogen CARBOPOX®: premix technology with oxygen and natural gas/propane LINFIRE®: technology for after mixing CARBOFLAM®: Surface and post-mixing burners with oxygen and acetylene Premix burners operate more efficiently than name burners. In addition, hydrogen/oxygen based technologies are more efficient than natural gas/oxygen or propane/oxygen based technologies. Linde premix technology with oxygen and hydrogen is the solution of choice for high-value applications where speed, quality and efficiency are important. Linde premix technologies at a glance: Gas premixing Electropneumatic control units Water-cooled/uncooled burners Standard burners/customized special burners 100 % stainless steel Capacity control, control units, exact pressure control and exact regulation of the gas ratio for each burner G Acetylene PLEASE NOTE: You must log in to order this product Add to cart Oxygen 2.5 PLEASE NOTE: You must log in to order this product Add to cart Propane (rent) PLEASE NOTE: You must log in to order this product Add to cart Propane (deposit) PLEASE NOTE: You must log in to order this product Add to cart Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ Safety Safety General questions about gas Gas transport General questions about gas What is pressure? Pressure is a force acting on an area which is caused by the compounds of the particles or by the weight that is placed on a surface. The pressure in a cylinder has a gas pressure of 1,013 bar, and because of this there is a pressure equilibrium with the air around the cylinder. What is meant by vapour pressure? Above any liquid surface, there is a vapour pressure, because particles detach from the surface of the liquid due to their own momentum. The pressure which is thereby brought about depends exclusively on the temperature of the fluid. The vapour pressure curve shows the dependence between the vapour pressure and the temperature of the fluid. The temperature that is required to generate a vapour pressure of 1 bar above the liquid is the boiling point of a substance. What effect does temperature have on gas? In addition to the pressure, the temperature has an influence on the gas. Under heating the gas expands, just as is the case with solid materials. An iron rod expands under heating and shrinks when it cools. With an increase in temperature the gas particles will move more rapidly. Because the speed increases, the particles collide more frequently with each other and with the wall of the package. The pressure in the cylinder thus increases as the temperature increases. For the sale of gases, we start from a content calculation on the basis of a temperature of 15 °C. On this 200 bar of content of pure gases is calculated. What about liquefying gases? Any gas can be liquefied by cooling back to the pressure corresponding to the boiling point. However, it is a requirement that this is below the so-called "critical temperature", because above it is not possible to liquefy. A distinction is drawn between "pressurised liquefied" gases, which can be liquefied by increasing the pressure at ambient temperature (e.g., propane or carbon dioxide), and "cryogenic liquid" gases (e.g., oxygen or nitrogen). How much gas is in a cylinder? The space that a specific amount of gas takes up decreases as the pressure increases. Therefore, the greater the pressure in the cylinder, the more gas there is in it. It follows from this that: the amount of gas in a gas cylinder is determined by the volume of the bottle and the pressure which the gas is under in the bottle. For most gases, the following applies: Gas content of a gas bottle = volume of the cylinder x pressure in the bottle. Example: In a steel cylinder of 50 litres water capacity filled at 200 bar there are 200 x 50 = 10,000 litres of gas or 10 m3 of gas. You can check how much gas there is in a cylinder if you know the size of the cylinder and the filling pressure. This is true only for compressed gases, but not liquefied or dissolved gases, for which the content of the bottle can only be determined by weighing. Gas transport The driver must follow special rules when he comes to make the delivery, how can I ensure that? You can inform us about the guidelines for our drivers via the online contact form. We will ensure that the drivers are informed by an instruction and a message on their delivery list. ]

-

[ Liquid nitrogen Liquid nitrogen For various applications. Liquid nitrogen is used in a variety of industries. From small quantities for treating skin conditions, to shrinking metal, to preserving samples. Linde supplies liquid nitrogen from 1 to 2,000 liters for all your cryogenic applications. The production of nitrogen is based on the separation of ambient air into its components. In our air separation plants, that air is purified and then compressed. Then the compressed air is cooled to extremely low temperatures. It is then compressed again to liquefy the air and separate it by distillation into nitrogen, among other things. In the process, the temperature of liquid nitrogen drops to -196°C. LIN-service Cryocare Cryo-courier More information PIB Stikstof liters PIB MEDISPEED bulk PIB MEDISPEED LIN Service Gebruiksaanwijzing MEDISPEED LIN-service Nitrogen delivery via our LIN-service Through the LIN-service, Linde fills the cryogenic vessel that is at your location. This can be an owned vessel, but you can also rent vessels from us. Linde delivers medical CE marked MEDISPEED® and technical nitrogen to all regions of the country on designated route days. You can either discuss a standard delivery schedule or order on demand. The quantity of nitrogen can range from 10 to 2,000 liters. The concept Delivery on site with compact bus Delivery in ownership or rental vessel Invoicing based on liters delivered Delivery on route days per region Delivery on demand or by fixed schedule Applications Freezing and storing samples Treatment of skin disorders Molecular cooking Cold shrink Metal hardening Cryocare Nitrogen delivery for general practitioners. Our nationwide distribution network for general practitioners and dermatologists provides timely delivery of small quantities of medical CE marked liquid nitrogen, MEDISPEED®, in an approved cryogenic vessel. Medical CE marked liquid nitrogen, MEDISPEED®, is used to treat warts and sometimes for minor surgical procedures. 1.5 liter, 6 liter or 8 liter vessels are used. Linde Healthcare does not use thermos flasks for delivery. All our vessels are specifically designed for storage and use of medical CE marked liquid nitrogen. The empty vessels are delivered to the practice address full against empty according to an agreed exchange frequency. In practice, this means that a general practitioner or dermatologist receives a full keg of liquid nitrogen every four weeks. The concept 1.5 liter / 6-8 liter drum Exchange full against empty Fixed delivery frequency Including use of nitrogen drum With oxygen meter from 3 liters Advantages for the general practitioner Safe storage vessels of liquid nitrogen No transport risks No purchase costs Always know when liquid nitrogen is on hand Number of deliveries tailored to requirements Cryo-courier Supply of nitrogen for storage of semen at livestock farms. Liquid nitrogen is replenished every eight weeks according to a set pattern for storage of semen and embryos, such as at horse farms. During each delivery, all nitrogen vessels are checked and refilled. As a result, you are completely relieved in this area. The concept Delivery +/- 10 liters of nitrogen On fixed route days 1 x per 8 weeks The barrel is the property of the customer Fixed amount per delivery Filling on location Storage vessels can also be ordered through the CryoCourier to store your material under the right conditions. The Toro vessel, with a shelf life of 158 days, is ideally suited for sperm storage. It is equipped with 6 canisters and offers capacity to store 720 1/2cc straws. Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ Lottery January 2024 LOTTERY Win a PPE safety giftbasket of approx €445,- January lottery Get a chance to win a safety package! Place an online order between January 1, 2024 and January 31, 2024 and get the chance to win a PPE safety package worth approximately €445 ! How can I participate? While completing your order, enter the promo code 'WINACTIE' in the discount code field. After completing the order, the order you placed will automatically enter as a lottery ticket for the win promotion. Can I enter multiple orders? Yes, all orders placed on this website (www.linde-gas.nl/shop) with promocode 'WINACTIE' added will automatically participate in the lottery. Thus, multiple orders can be placed on the same customer number. When do I need to place the order? To participate in the win promotion, the order must be placed during the promotion period, which runs from January 01, 2024 00:00:00 to January 31, 2024 23:59. The order must have a minimum order amount of €20. How do I add the promo code to an order? Na het toevoegen van de producten in uw winkelwagentje, kunt u vervolgens rechtsboven klikken op het winkelwagen icoon. Daar ziet u de producten die u heeft toegevoegd en daaronder ziet u aan de linkerkant een veld met 'kortingscode'. Daaronder kunt u de promocode invoeren. Klik vervolgens op het blauwe veld ernaast met 'verzenden' om de promocode aan uw bestelling toe te voegen. After adding the products in your shopping cart, you can then click on the shopping cart icon at the top right. There you will see the products you have added and below that you will see a field on the left side with 'discount code'. Below that, you can enter the promo code. Then click on the blue field next to it with 'send' to add the promo code to your order. If you see the text: 'WINACTIE: Minimum purchase amount to qualify for discount: 20' appears below the field, you have succeeded and the discount code has been added to your order. Will I get a discount on my order if I add the promo code? The promo code WINACTIE does not provide a discount. What can I win? The winner of the win promotion will receive a PPE safety package, which includes work pants, winter jacket, ear muff, first aid kit, goggles, fire blanket. The clothes in the safety pack have the most common sizes. These cannot be exchanged after the event. Terms & conditions for participation in the lottery: These terms and conditions apply to the January lottery organized by Linde Gas Benelux. By participating in the contest, the participant agrees to the terms and conditions below. This is a translation of the original terms & conditions in Dutch. In the event of any discrepancy, the Dutch version shall prevail. The January lottery is organized by Linde Gas Benelux. The lottery is valid for customers who place an order on www.linde-gas.nl/shop during the period 01 January 2024 00:00 00 until 31 January 2024 23:59 and who have added promo code WINACTIE to their order. Promo codes can be added to the order in the second page of the ordering process. As a customer, you can participate in the lottery with multiple orders. The prize is a PPE safety package worth approximately €445,- In the following cases you cannot take part in the promotion: a. If you are not a customer of Linde Gas Benelux b. If your company is not registered in the Netherlands. c. If you cancel the order on your own initiative after placing it. After the promotional period, the winner will be determined. This winner will be determined impartially by drawing lots. The winner will be notified by Linde Gas Benelux by e-mail. If the winner is unreachable, fails to collect his/her prize or fails to respond within two weeks, the prize may be withdrawn and awarded to another prize winner to be determined by the draw. No correspondence can be entered into regarding the results and awarding of the prize. The value of the prize cannot be paid out in cash. ]

-

[ Clean energy & Hydrogen Clean energy & hydrogen Clean energy & hydrogen Hydrogen is the most abundant element in the universe Although light and small, hydrogen is a powerful energy carrier - one kilogram of hydrogen contains three times as much energy as kerosene. It can be used to store excess renewable energy and then transported underground through an extensive network of pipelines or overland by truck to be used in a wide range of applications, from mobility to heavy industry. Because of its versatility, hydrogen is proving to be an important factor in the transition to low-carbon and carbon-free energy - clean energy that contributes to climate change goals. On this page you will find information about climate change and climate change agreements, what hydrogen can do for them and what role Linde plays in the production, transport and use of hydrogen to support the energy transition. The threat of climate change The consequences of climate change - global warming and the accompanying shifts in climate patterns - are becoming increasingly visible for the environment, society, and the global economy. Climate change is not a threat that is far away - it is happening now.is - het gebeurt nu. 1 The global average temperature in 2021 was about 1.11 (± 0.13) °C higher than pre-industrial levels (1850-1900). 2021 is the 7th consecutive year (2015-2021) in which the global average temperature was at least 1°C higher than pre-industrial, according to data collected by the World Meteorological Organization. 1 In 2020, greenhouse gas concentrations reached a new high. Carbon dioxide levels reached 150% of pre-industrial levels (Source: United Nations) 1 Without adaptation measures, the number of people deprived of adequate water for at least one month per year will increase from 3.6 billion today to more than 5 billion in 2050. 1 With higher temperatures, a decrease in crop yields can be expected. Heat stress also leads to loss of quality and increased wastage. 2 Emissions must fall by 7.6 percent per year between 2020 and 2030 to keep temperatures from rising above 1.5°C, and by 2.7 percent per year to stay below 2°C. 1 1 - https://www.un.org/en/climatechange/science/key-findings 2 - https://www.sciencedirect.com/science/article/pii/S0095069621000450 Watch the video to understand how hydrogen enables decarbonization in different application areas. International agreement on climate change The Paris Agreement, an international agreement on climate change, was adopted in 2015. It aims to limit the rise in temperature from pre-industrial levels to well below 2°C, preferably 1.5°C, by reducing greenhouse gas emissions, increasing the share of renewable energy and improving energy efficiency. As a result, more and more countries, regions, cities and the companies that supply them are setting ambitious carbon neutrality targets and looking for solutions that will enable them to achieve them - hydrogen will play an important role in the new energy system. Hydrogen as a catalyst for decarbonization. Hydrogen as a pathfinder for decarbonization To combat climate change, countries around the world are working on ambitious plans to switch to low-carbon energy sources, with hydrogen as the centerpiece. It is a versatile, clean and safe energy carrier that can be used as a fuel or as an industrial feedstock. When used in a fuel cell, it produces no emissions because it emits only water vapor, making it a strong contender to decarbonize transportation. It can be stored and transported in liquid or gaseous form with high energy density and is available for a wide range of applications that can reduce their carbon footprint to zero emissions. With increased use of clean hydrogen and subsequent improvement of associated technologies, hydrogen could be the most competitive low-carbon solution in terms of total cost of ownership (TCO) by 2030 for more than 20 applications, including long-haul trucks, shipping and steel. On the road to green hydrogen Hydrogen is colorful - it takes on different colors depending on the intensity of net carbon dioxide emissions, the production method and the feedstock content, with green hydrogen with zero or negative net CO2 emissions being the ultimate goal. Linde has been harnessing the power of hydrogen for more than 100 years, continuously investing in effective and economical processes to deliver gray, blue and ultimately green hydrogen. We can produce hydrogen from a range of raw materials and natural resources. We use steam methane reforming (SMR) to produce gray hydrogen from natural gas, liquefied petroleum gas (LPG) or naphtha. SMR is currently the most widely used process for producing hydrogen. Gray hydrogen can be converted to blue hydrogen by using carbon capture and storage technologies. Green hydrogen can be produced by electrolysis using renewable energy. An alternative method for producing green hydrogen is methane steam reforming using biomass as a feedstock. Gray and blue hydrogen are important stages on the road to green hydrogen because they allow for the development of the necessary framework and infrastructure while green hydrogen production reaches the required scale. Hydrogen in action Green steel production: Using hydrogen in combination with oxygen from Linde, we work with customers to make steel production processes more sustainable. By using less natural gas and replacing it with H2 and O2, we prevent CO2 and other emissions. A good example of the application of hydrogen in practice. Public transport on hydrogen: Linde's hydrogen is used to power a fleet of buses in public transport in the Emmen region. As a result, the buses no longer emit exhaust gases but pure water. TU Delft's Forze race car: A hydrogen-powered race car, sponsored by Linde. The Forze team at TU Delft is constantly working on the development of a new 'Forze' model. Together with students from Rotterdam University of Applied Sciences, the team aims to develop sustainable technology and present it in an attractive way. The Shell Eco-marathon: This event is one of the world's most challenging innovation competitions for students, and takes place annually in Europe, America and Asia. For many years, Linde has been a global partner of the Shell Eco-marathon, as the exclusive hydrogen supplier. G Hydrogen 5.0 Detector PLEASE NOTE: You must log in to order this product Add to cart Hydrogen 5.0 GENIE PLEASE NOTE: You must log in to order this product Add to cart Hydrogen 6.0 HiQ PLEASE NOTE: You must log in to order this product Add to cart Hydrogen droog 3.0 PLEASE NOTE: You must log in to order this product Add to cart Request a consultation Contact us for a consultation about Linde Gas Benelux applications, products and/or services. Referred By Country *Lead Currency EUR - Euro Titel Lead source Web Industry Please select Chemistry & Energy Food & Beverage Metallurgy & Glass Manufacturing Healthcare Electronics Government Water Hydrogen Mobility SRA Others Salutation* Please select Mr. Mrs. Company* First name* Last name* Address* Zip code* City* Phone* E-Mail* Description (if applicable, please also mention your customer number)* ]

-

[ Gas per pipeline Gas per pipeline When industries require extremely large amounts of gases for their production Oxygen is used in thousands of tonnes a day for petrochemicals or for steelmaking. Inert nitrogen is used in the chemical industry or as liquefied gas in food freezing. Hydrogen is used in many refineries in large amounts to improve the quality of petrol, according to legislation and carbon monoxide as a basic product in the chemical industry. These extremely large requirements of oxygen, nitrogen, hydrogen, carbon monoxide or syngas can be supplied via a pipeline or pipeline networks. A production plant can be placed next to an individual customer or several production plants may be connected to a pipeline network which serves a number of customers located within the same industrial cluster or geography. Linde offers standard and customised solutions based on our long tradition in the production of Air Separation Plants and HyCO plants for all industries and in a wide variety of sizes and gas qualities. As this mode of supply requires intensive individual consultancy, Linde positions specialists in the main regions of the world for direct customer support. ]

-