you are currently visiting our website in a browser that is not supporting our website.

Flame spraying

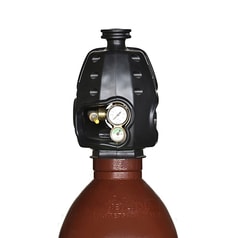

Of the various process variations of thermal spraying, flame spraying is one of the most cost-effective, since acquisition, installation and operation require comparatively little effort. In flame spraying, the powder or wire spray additive is usually most effectively melted on or off by an oxy-acetylene flame, and thus also makes a major contribution to the economy of the process.

Melting down of flame sprayed coatings

After coating, some flame-sprayed coatings require thermal post-treatment, known as melting down, to eliminate porosity in the applied material and produce a dense, homogeneous and wear-resistant coating.

The right torch for optimum surface properties

We offer a range of LINDOFLAMM® custom torches to help you achieve the exact characteristics and properties you require from your surface coating. Our torches not only provide harder, denser coatings, but also reduce processing time and improve accuracy. What's more, they can be fully automated.

The right fuel gas for melting down self-flaming flame spray coatings

Various hydrocarbons can be used as fuel gas for thermal spray processes. Particularly powerful fuel gases such as acetylene are preferably used for melting down. The very hot acetylene flame melts the coating material and heats the substrate, improving the bond between the coating particles and preventing the formation of oxides due to the reducing flame.

With our LINDOFLAMM® offering, our customers benefit not only from state-of-the-art burner technology, but also from related services such as consulting and support during design and installation. Each concept is tailored to specifically meet our customers' requirements. Our highly qualified engineers will train your staff on site and design your gas supply system to meet your requirements and specifications.