Pour bénéficier d’un affichage optimal de la boutique en ligne de PanGas, vous avez besoin pour le navigateur de la version minimale suivante:

• Internet Explorer 9.0

• Mozilla Firefox 38

• Safari 8

• Chrome 45

Veuillez vous assurer que JavaScript est activé dans les paramètres de votre navigateur.

CRYOCLEAN® Dry ice cleaning

Optimal cleaning results with an effective, environmentally friendly solution, specially developed for difficult cleaning tasks in a production environment

There is hardly an industry where cleaning equipment, product or infrastructure is not required. While there are a wide range of options for cleaning, many have drawbacks. Water-based cleaning can leave moisture behind, and often requires post-treatment of water containing cleaning agents and the removed contaminants. Cleaning with solvents causes the emission of volatile organic mixtures. A dry abrasive blasting process may again be too aggressive for some cleaning problems. The dust generated in the process is harmful to health and waste disposal can become pricey.

CRYOCLEAN® CRYOCLEAN® snow+ CRYOCLEAN® pellet cleaningMore information

CRYOCLEAN®

CRYOCLEAN® is an attractive and proven alternative to traditional cleaning methods. As a cleaning agent it uses solid carbon dioxide, also known as dry ice. Similar to sandblasting, small ice particles are launched with compressed air and shot onto the contaminated surface.

The cleaning effect of dry ice is based on a combination of embrittlement of and cracking of the dirt, kinetic momentum and a gas flow generated by the explosive sublimation of dry ice on impact. Unlike other cleaning methods, CRYOCLEAN significantly avoids or reduces the use of post-impact cleaners. It works without solvents and leaves no moisture behind, so equipment can often be cleaned in situ.

Linde offers a number of CRYOCLEAN alternatives, suitable for different cleaning tasks. CRYOCLEAN® pellet cleaning works with pre-fabricated pellets and is mainly used for manual cleaning of equipment and tools. CRYOCLEAN® snow cleaning is mainly used as an upstream or downstream process step in fully automated serial manufacturing of products... CRYOCLEAN® snow+ combines the advantages of dry ice and abrasives for manual cleaning during production.

CRYOCLEAN® snow+

CRYOCLEAN® snow is an innovative technology for cleaning and pretreating surfaces using small dry ice particles. CRYOCLEAN snow+ is intended for cleaning tasks with varying cleaning intensity and abrasiveness. Surfaces may be relatively clean overall, but there may appear to be locally highly contaminated, chemically altered or even corroded areas.

As a unique combination of dry ice blasting and sandblasting, CRYOCLEAN snow+ is a flexible cleaning method that allows the user to vary the ratio of CO2 to abrasive depending on the surface condition. Areas with soft dirt particles can be cleaned with dry ice particles, which were generated by injection of liquid carbon dioxide into special nozzles. Compressed air and Laval nozzles are used to eject the particles onto the surface to be cleaned.

Only in areas where it is really necessary, an abrasive cleaning agent can be added to the blasting unit as needed. This allows CRYOCLEAN snow+ to benefit from the advantages of both methods: avoidance of moisture and solvents through the use of dry ice, and the abrasiveness of solid abrasives. Thus, operating costs can be reduced by reducing the amount of abrasives required and the associated costs of waste disposal. CRYOCLEAN snow+ is specifically designed for manual or semi-automatic operation. Linde offers special, patented blasting equipment, supply solutions for liquid carbon dioxide (CO2 in tanks or in bulk in combination with our PRESUS® C supply systems) and different types of abrasive blasting media.

CRYOCLEAN® pellet cleaning

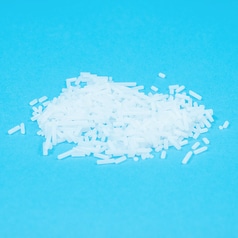

CRYOCLEAN® pellet blasting is a cleaning technology in which 3 mm ice pellets are accelerated in a stream of compressed air, and shot at very high speeds onto a surface to clean it.

Dry ice pellets are quite soft and much less dense than other media used in blast cleaning (e.g. sand, glass or plastic pellets). Upon impact, the pellets sublimate almost immediately, transfer minimal kinetic energy to the surface upon impact, and produce minimal wear in the process. The sublimation process absorbs a large amount of heat from the surface, producing crack loads due to the thermal shock. The rapid transition from solid to gaseous state also produces microscopic shock waves, which are believed to aid in contaminant removal.

Benefits of pellet cleaning:

- Clean blasting with dry ice reduces downtime because it eliminates the need to disassemble machines

- Because dry ice cleaning is moisture-free, drying is not necessary

- It is bacteria resistant, meaning that it provides not only an effective cleaning mechanism, but also a sterilization process, making it especially attractive for food and science applications

- No additional contamination is produced that must be removed again, as is often the case with water- and solvent-based processes

CRYOCLEAN pellet blasting is used in almost every industry. Some examples:

- Automotive: Cleaning of engine blocks, molds and forms, spray booths

- Breweries: Removal of yeast residue from barrels and tanks

- Electricity: Cleaning electrical motor housings, stators and windings, control panels, safety switches, substations and line isolators

- Electronics: Removal of melting agents and residues deposited on circuit boards of process equipment and drying ovens

- Food products: Cleaning of process equipment, conveyors, mixing vessels, ovens, floors, molds and extrusion dies

- Foundries: Moldings, dies, injection molding machines, mixers, hoppers, fans

- Municipal authorities: Cleaning of drains, removal of chewing gum residue, surface renovation of buildings and monuments

- Paper: Removal of paper and wood pulp from processing equipment

- Pharmaceuticals: Cleaning of reactors, mixers, storage tanks and molds

- Plastics: Cleaning of molds, extrusion dies, furnaces and mixing machines

- Printing: Removal of ink, coatings and residual paper dust